I. Introduction:

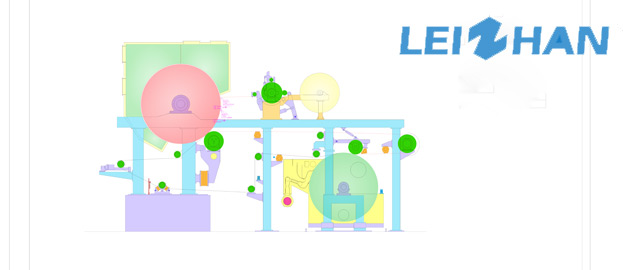

Positive slurry cylinder mould tissue paper machine is mainly used to produce tissue paper. The paper machine is divided into several parts: net groove, cylinder mould part, press part, drying part and reeling part.

II. Net groove:

Square cone pipe pulp inlet, movable curved plate pulp machine, control and stabilize the pulp speed and concentration by adjusting and controlling pulp inlet pressure and curved plate aperture of inlet pipe.

III. Cylinder mould part:

One cylinder mould, main parts: couch roll, back roll and frame and so on.

IV. Press part:

Carrier roller press is made of idler roller and big diameter cylinder, and equip with one covered rubber metal roll. Carrier roller press includes guide felt roll, felt suction box and a felt. the idler roll press’s pressure method is corrugated tire pressure.

V. Drying part:

Φ3000/Φ3600 dryer cylinder, individual drive and equip with closed type hot blast air hood, a wrinkle scraper and a clean scraper. Pressured way is air cylinder pressure.

VI. Reeling part:

Pneumatic horizontal type paper reeling machine, air cylinder pressure. It installs on the top platform of cylinder mould part.