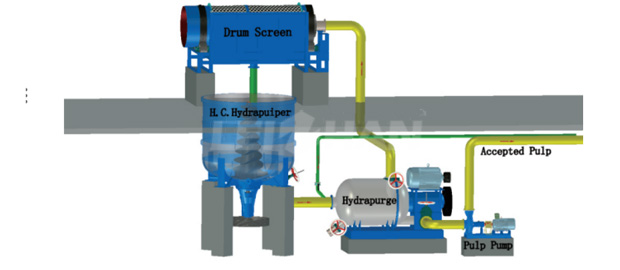

The high consistency continuous pulping system uses high-consistency pulping technology, which can crush and remove impurities from waste paper (office waste paper, high wet strength, etc.) under high-consistency (14-18%) conditions, effectively improving the quality of waste paper and processing efficiency and pulp quality. The high consistency continuous pulping system include high consistency hydrapulper, drum screen, hydrapurger. Each equipment is connected through conveying equipment to realize continuous feeding, crushing, screening and discharging of waste paper raw materials.

High Consistency Hydrapulper: Under the conditions of high consistency and heating, the pulper uses the combined action of mechanical shearing force and hydraulic shearing force to quickly dissociate waste paper into single fibers. At the same time, chemicals such as deinking agent are added to remove impurities such as ink particles separated from the fibers.

Hydrapurger: During in high consistency continuous pulping system, the hydrapurger is mainly used to accept the accept pulp from the H.C. Hydrapulper. After the pulp is crushed by the pulper, it enters the roughing machine and separates the impurities from the accept pulp through the sieve plate.

Drum Screen: The drum screen is installed after the roughing machine and is mainly used to further screen the slurry.

Leizhan supply unit pulp machine for high consistency conditions pulping system. Welcome to contact us for more details. Email address: leizhanchina@gmail.com.